We have a large inventory, fast delivery and low prices.

Get A Quote: sales@shanqisteel.com

Enhanced Surface Protection – The fingerprint-resistant galvanized steel plate provides an additional protective coating that effectively prevents fingerprints, sweat, and corrosion, maintaining a clean and glossy appearance.

Versatile Application Options – Available in multiple types such as fingerprint-resistant, phosphated, and passivated plates, offering flexibility to meet different industrial and aesthetic requirements.

Improved Corrosion and Wear Resistance – Phosphating and passivation treatments strengthen surface durability, enhancing resistance to oxidation, rust, and environmental factors.

Excellent Processing Performance – Both ordinary and fingerprint-resistant galvanized steel plates feature stable mechanical properties and good formability, making them ideal for use in components that require no further surface treatment.

| Availability: | |

|---|---|

Product Description

Galvanized sheet refers to a steel plate coated with a layer of zinc on its surface. Galvanizing is one of the most economical and effective methods for preventing corrosion, with approximately half of the world’s zinc production used for this purpose. The primary function of galvanizing is to protect the steel plate’s surface from rust and extend its service life by applying a layer of zinc coating, resulting in what is known as a galvanized steel plate.

Product name | Galvanized Steel Plate |

Thickness | 0.12-3mm |

Width | 100-1500mm or according your needs |

Tolerance | Thickness: ±0.01mm Width: ±2mm |

Zinc Coating | 60-300m³ |

Surface Treatment | Oiled, Passivation, Dry |

Spangle | Regular, Small, Big, Zero |

Hardness | Full Hard, Half Hard, Soft |

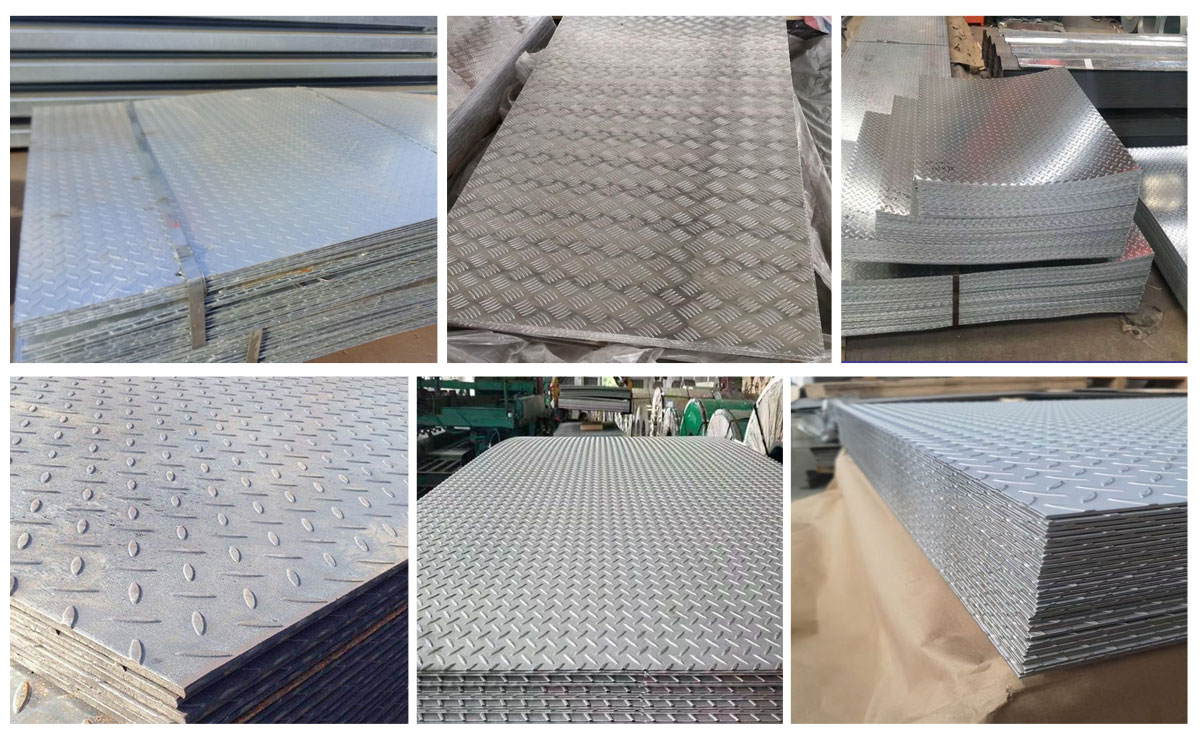

Package | Standard export package (Plastic film in the first layer, second layer is Kraft paper. Third layer is galvanized checker plate) |

Application | Construction, Industrial panels, Roofing and siding for painting |

Trade Terms | EXW, FOB, CFR, CIF, ect. |

Delivery time | Stock steel/Steel for simple cutting/Small amount of general standard steel: about 5-20 days for delivery; Custom steel/bulk steel: about 15-30 days for delivery. Contact us for specific delivery times. |

Plating Definition

(1) Normal Spangle Coating

In the natural solidification process of the zinc layer, zinc crystals grow freely, forming a coating with a distinct spangled pattern.

(2) Small Spangle Coating

During the zinc layer’s solidification, the growth of zinc crystals is artificially controlled to produce the smallest possible spangle structure.

(3) Zero Spangle Coating

By adjusting the chemical composition of the plating solution, a coating without visible spangle patterns is obtained, resulting in a smooth and uniform surface appearance.

(4) Zinc-Iron Alloy Coating

After the steel strip passes through the galvanizing bath, it is heat-treated to form a zinc-iron alloy layer throughout the coating. This type of coating appears dark gray with no metallic luster and can be directly painted after simple cleaning, without additional treatment.

(5) Differential Coating

This process applies different zinc layer weights to each side of the galvanized steel sheet according to specific application requirements.

(6) Skin Pass (Smoothing)

A light cold-rolling process performed on galvanized steel sheets to:

Improve surface appearance or coating adhesion;

Prevent slip lines (Lüders lines) or creases during subsequent processing;

Temporarily minimize surface irregularities.

The products of galvanized steel sheet are mainlyused in such industries as construction industrylight industry,automobile industry,agriculture-livestock-fishery industry and commercial industry etc.For construction industry,galvanized steel sheet can be used to produce the anti-corrosive roof panels and roof grille etc.for industrial and civil construction usage.For light industry,producing appliance housings, civil chimneys and kitchenwares etc. For automobile industry, producing anti-corrosive auto parts for cars etc.For agriculture-livestock-fishery industry, producing appliances for storage and transportation of grain, frozen processing appliances for meat and aquatic products and so on.For commercial industry, producing appliances for storage and transportation of goods and materials, packaging appliances and so on.

FAQ:

Q: What products does your company have?

A: Our company produces all kinds of galvanized sheets, coils, tubes, steel strips, PPGI/PPGL, Roofing Steel Sheet, etc. Production experience, support customization.

Q: What are the advantages of your company?

A: (1): Prime quality and Competitive price.

(2): Excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Samples can be provided as your requirements.

Q: What is your terms of payment ?

A: Can be negotiated by both parties. If you have another question, pls feel free to contact us as below

Q: What about your price?

A: Our price is very competitive.

Pls feel free to contact us if you are interested in our products.

Q: How long is your delivery time?

A: Stock steel/Steel for simple cutting/Small amount of general standard steel: about 5-20 days for delivery; Custom steel/bulk steel: about 15-30 days for delivery. Contact us for specific delivery times.