We have a large inventory, fast delivery and low prices.

Get A Quote: sales@shanqisteel.com

Views: 0 Author: jim Lee Publish Time: 2022-02-11 Origin: Site

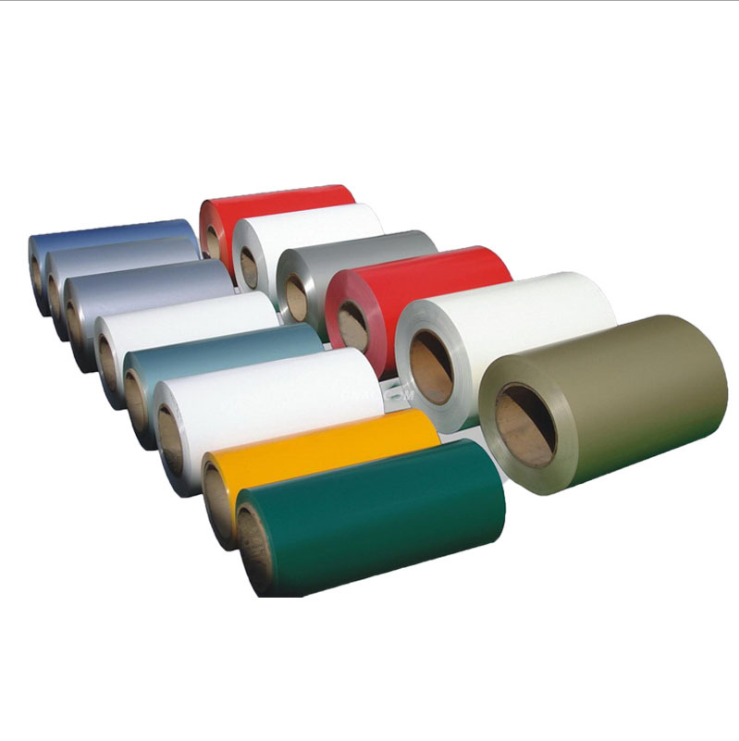

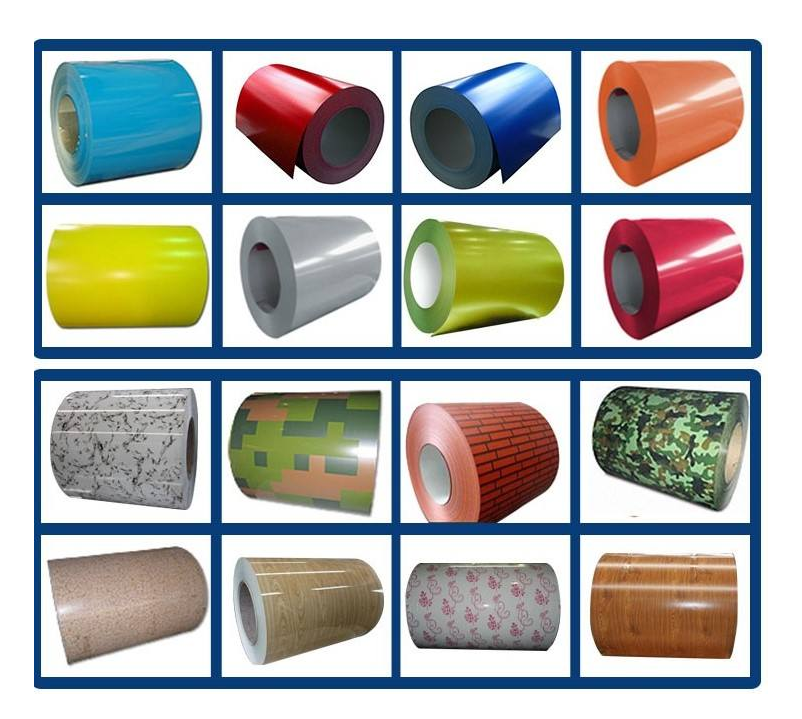

Color-coated coils are based on hot-dip galvanized sheet, hot-dip galvanized sheet, electro-galvanized sheet, etc. After surface pretreatment (chemical degreasing and chemical conversion treatment), one or several layers of organic coatings are applied on the surface. The product is then cured by baking. The color-coated steel strip using hot-dip galvanized steel strip as the base material is protected by the zinc layer, and the organic coating on the zinc layer plays a covering and protective role to prevent the steel strip from rusting, and the service life is longer than that of the galvanized strip. 1.5 times.

Color-coated coil substrate classification:

Hot dip galvanized substrate

The product obtained by coating the organic coating on the hot-dip galvanized steel sheet is the hot-dip galvanized color-coated sheet. In addition to the protective effect of zinc, the organic coating on the surface of the hot-dip galvanized color-coated sheet also plays the role of insulation and protection, preventing rust, and the service life is longer than that of the hot-dip galvanized sheet. The zinc content of the hot-dip galvanized substrate is generally 180g/m2 (double-sided), and the maximum galvanized amount of the hot-dip galvanized substrate for building exterior is 275g/m2.

Hot-dip Al-Zn substrate

The hot-dip galvanized steel sheet (55% Al-Zn) is used as the new coating substrate, and the content of aluminum and zinc is usually 150g/㎡ (double-sided). The corrosion resistance of hot-dip galvanized sheet is 2-5 times that of hot-dip galvanized sheet. Continuous or intermittent use at temperatures up to 490°C will not severely oxidize or produce scale. The ability to reflect heat and light is 2 times that of hot-dip galvanized steel, and the reflectivity is greater than 0.75, which is an ideal building material for energy saving.

Electro-galvanized substrate

The electro-galvanized sheet is used as the substrate, and the product obtained by coating the organic paint and baking is the electro-galvanized color-coated sheet. Because the zinc layer of the electro-galvanized sheet is thin, the zinc content of the electro-galvanized sheet is usually 20/20g/m2, so this product is not suitable for use. Make walls, roofs, etc. outdoors. But because of its beautiful appearance and excellent processing performance, it can be mainly used in home appliances, audio, steel furniture, interior decoration, etc.